Custom Film Cutting

For Filmcutter, roll cutting is a department of fundamental importance, dedicated to converting and packaging the material in order to deliver the product in a format suitable for its use by the end customer. Therefore, in addition to the manufacturing of the product itself, Filmcutter has always integrated its offer with the cutting of the material to size.

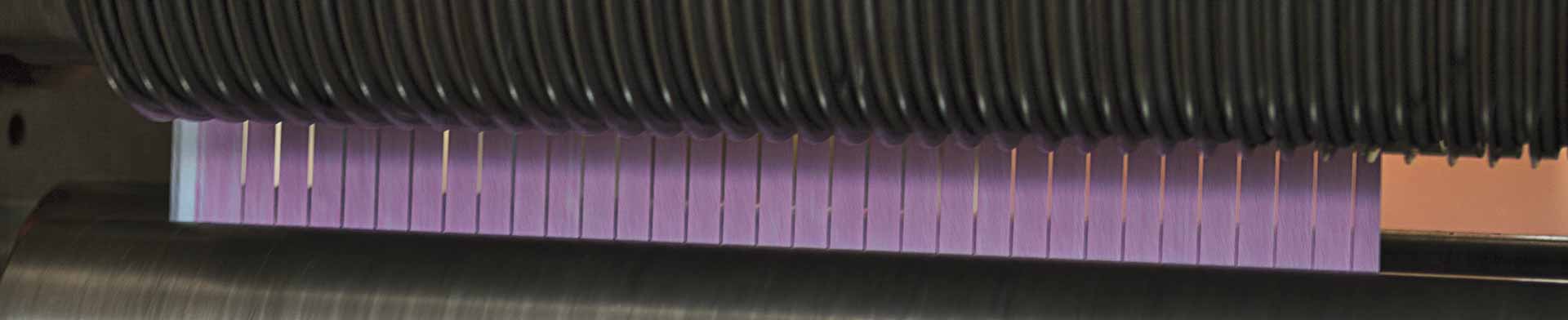

The company's technological park has 6 cutting machines including some single-shaft and others double-shaft, each suitable for processing materials with different characteristics to guarantee the best quality of the material to the customer. The machinery available allows us to process films or flexible laminates with thicknesses between 10 microns and 1.5 mm, obtaining rolls in heights between 8 and 2300 mm.

These cutting processes, fully integrated into the company's production process, allow us to obtain a finished product with competitive costs and allow us to limit waste and processing scraps. At the same time, thanks to the company's continuous technological updating, they guarantee the best quality and reliability of the materials.

In particular, for the electrical sector, continuous control of the DIelectric rigidity performance is integrated into the cutting process, ensuring customers technically compliant material in relation to this characteristic.

The cutting to size can also be carried out directly on the lamination and coating line. In this case, the process must be specifically designed in correlation with the product and can be implemented within the limits of the cutting precision required by the customer.

CUT TO SIZE IN ROLLS

Thanks to the 6 cutting machines the company can process different types of materials with thicknesses ranging from 20 microns to 1.5 mm and heights ranging from 7 mm to 2300 mm depending on the customer's needs.

Possibility to produce rolls with custom diameter depending on the needs.

CUTTING IN SHEETS

2 “sheet cutting” machines for cutting sheets/strips of material with maximum piece dimensions 1400mm x 2000 mm using a cutter on flexible supports.

The production is able to cover all customer needs and is divided into categories based on size, thickness of the material to be processed, production quantity.

Importance of this process

The custom cutting of film for electrical insulation is a valuable and highly specialized service in the electrical insulation industry. This process allows for obtaining insulating films with customized dimensions and shapes to precisely meet the specific needs of each application. Thanks to advanced cutting techniques and specialized machinery, it is possible to obtain custom insulating films with millimeter precision, ensuring perfect adaptability and high quality of the final product.

Custom cutting of film for electrical insulation is essential for a wide range of sectors and applications, from the electrical and electronics industry to automotive, renewable energy, and medical device manufacturing. This service allows for the creation of custom insulating components for transformers, electric motors, generators, printed circuit boards, and much more, ensuring reliable protection and optimal performance of the equipment and devices in which they are used.

One of the main advantages of custom cutting of film for electrical insulation is the ability to reduce material waste and optimize resource utilization. By cutting the insulating films to the exact dimensions required for the application, it is possible to minimize scraps and maximize production efficiency. This not only helps reduce production costs but also promotes sustainable and responsible practices, reducing the overall environmental impact of the production process.

Moreover, custom cutting of film for electrical insulation allows for greater precision and consistency in the dimensions of insulating components, ensuring better adaptability and greater reliability of the equipment and devices in which they are used. This is particularly important in high-precision sectors such as electronics, where even small variations in component dimensions can have a significant impact on the overall performance of the device.

The procedure

The custom cutting process involves the use of advanced machinery and computer-aided design (CAD) software to ensure optimal precision and consistency in the dimensions of insulating components. The insulating films are placed on the cutting table, and CAD software is used to create a precise layout of the pieces to be cut, optimizing material usage and minimizing waste. Subsequently, computer numerical control (CNC) machines perform the cutting of the insulating films according to the layout specifications, ensuring millimeter precision and impeccable finish.

Custom cutting of film for electrical insulation is a highly specialized service offered by experienced and qualified providers in the electrical insulation industry. Custom cutting service providers can collaborate with clients to understand their specific needs and provide tailored solutions that fully meet application requirements. Thanks to a combination of technical expertise, experience, and advanced technologies, custom cutting service providers can offer high-quality electrical insulation solutions with reliable performance for a wide range of industrial and technical applications.

In conclusion, custom cutting of film for electrical insulation is an essential service in the electrical insulation industry, allowing for obtaining custom insulating components with millimeter precision to meet the specific needs of each application. With its ability to reduce material waste, improve precision and consistency in component dimensions, and optimize production efficiency, custom cutting of film for electrical insulation helps ensure optimal performance and reliable protection of electrical and electronic equipment and devices.